Reliable Coatings from STS

Your Source for Tool Longevity

Our team is committed to understanding your needs as thoroughly as possible to provide you with high-quality, custom coatings to help you get the job done right.

PVD Coating Services from STS

Extend the useful life of your tooling and reduce your manufacturing cost by having us coat your cutting tools. But our coatings are not just limited to tooling. STS Coatings will coat any steel wear part from bearings to gears – even engaging parts.

About STS Coatings

STS offers the most experienced and fastest way to get the best finish for your material and cutting needs. Our superior specialists answer all your questions and offer the best solutions.

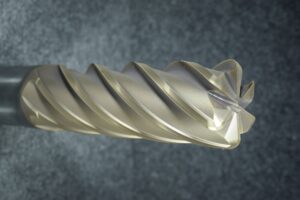

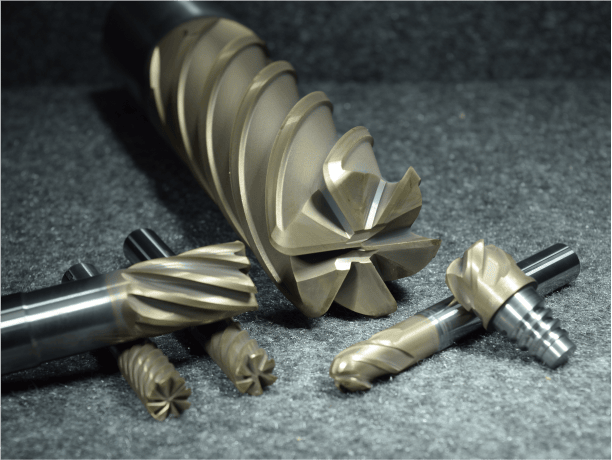

Get PVD coatings for your

- End Mills

- Drills

- Reamers

- Boring Tools

- Countersinks

- Form Tools

- Punches

- Grooving Tools

- Bits

- Engaging Component Parts

Types of PVD Coatings

-

TiN

Titanium Nitride

TiN was the first PVD coating developed and is still widely used. It’s an economical general-purpose coating offering corrosion resistance, heat transmission, and wear resistance. TiN coatings are often used in low-speed machining.

GENERAL STEELS

Color: Gold

Hardness: 2,300HV (Vickers Hardness)

Service Temp: 1112° F -

TiCN

TiCN

Chip and impact-resistant, TiCN coating works well for interrupted and low-to-medium speed cutting. It offers enhanced wear resistance to difficult materials like cast irons, copper, Inconel, and abrasive materials. The carbon adds hardness and surface lubricity.

HSS TOOLS – PUNCH STEELS

Color: Grey/Rose Brown

Hardness: 3,100HV (Vickers Hardness)

Service Temp: 850° F -

ALTIN

ALTIN

Based on nanolayers of Titanium and Aluminum, our AlTiN coating provides a low coefficient of friction and excellent toughness, combined with a high surface hardness. AlTiN is used on drills and milling cutters of steel and carbide for general applications and high-speed machining of ferrous materials with hardness up to 55-56 HrC.

Color: Grey

Thickness Range: 1 – 4 microns

Hardness: 3200HV (Vickers Hardness)

Maximum Operating Temperature: 1470° FLubricity: 0.5 coefficient of friction

-

AICrN +4

AICrN +4

Our AICrN coating has a high aluminum content with the added benefits of CrN, which possess excellent wear resistance properties. This coating excels in dry machining applications, milling, drilling, and especially hard material machining at moderate or better speeds. Teamed with good wear resistance and increased heat resistance.

Color: Anthracite

Thickness Range: 1 – 4 microns

Hardness: 3400HV (Vickers Hardness)

Maximum Operating Temperature: 1830° F

Lubricity: 0.3 coefficient of friction -

AuRoRa

AuRoRa

From the AlCrN family and its benefits, AuRoRa has added impact resistance and durability for the interrupted cut environment. AuRoRa works very well in Turning, Milling, Drilling, Tapping, and Gear Cutting in Stainless Steel and Super Alloys.

Color: Grey

Thickness Range: 1 – 4 microns

Hardness: 3400HV (Vickers Hardness)

Maximum Operating Temperature: 1830° F

Lubricity: 0.3 coefficient of friction -

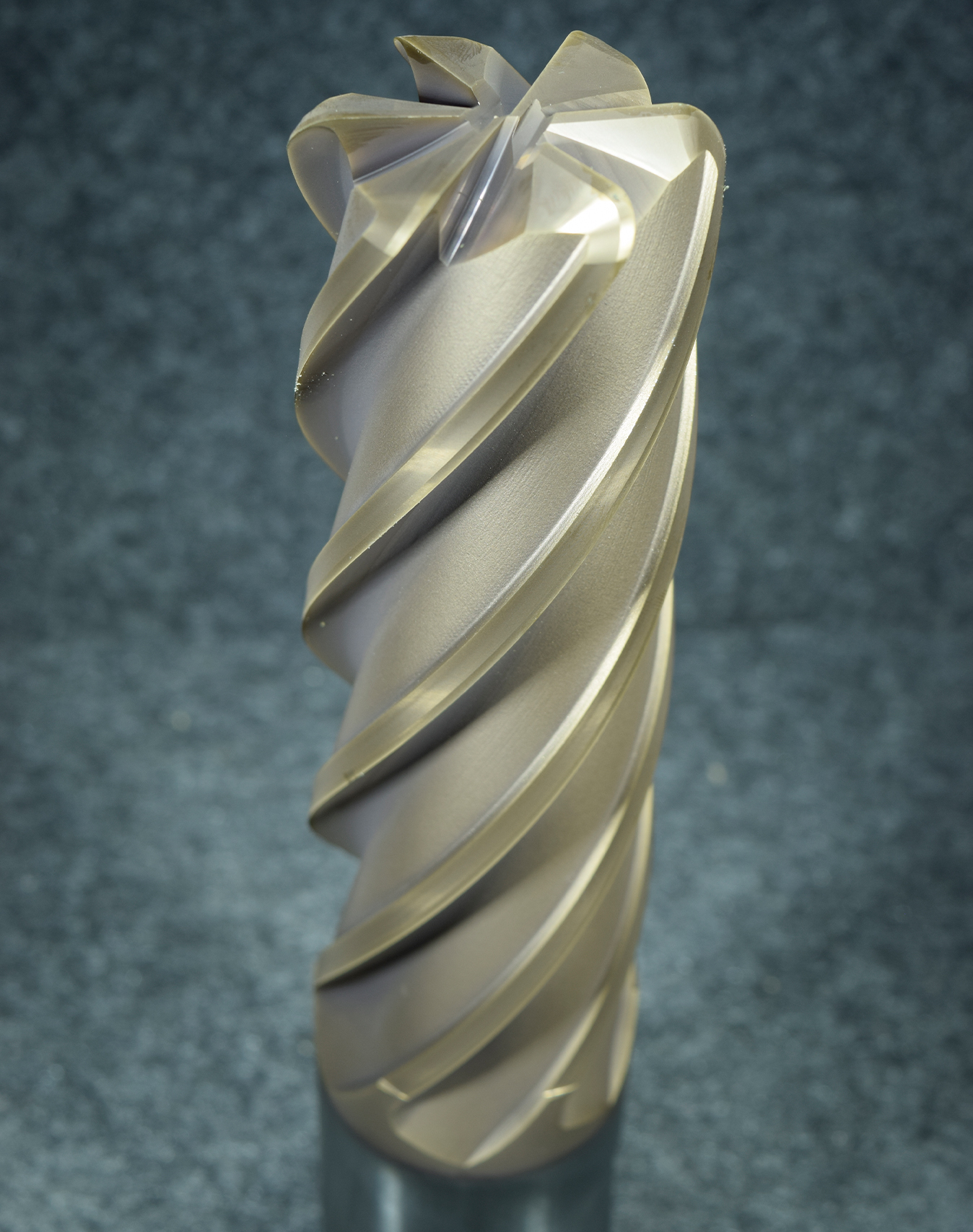

AITiSiN

AITiSiN (Hardmill)

Our latest coating STS-HARDMILL AITiSiN is a nanocomposite PVD coating. They are designed for hard, dry, and high-speed machining environments. HARDMILL exhibits exceptionally high resistance against oxidation and abrasion with a combination of high thermal hardness.

STS-HARDMILL results from a special structural composition deposited in our high-performance PVD coating system. STS-HARDMILL properties yield significant advantages for the high heat demands placed on your cutting tools today.

Color: Dark Bronze

Thickness Range: 1 – 4 microns

Hardness: 3500 HVO, 025

Maximum Operating Temperature: 1200° F

Lubricity: 0.5 coefficient of friction -

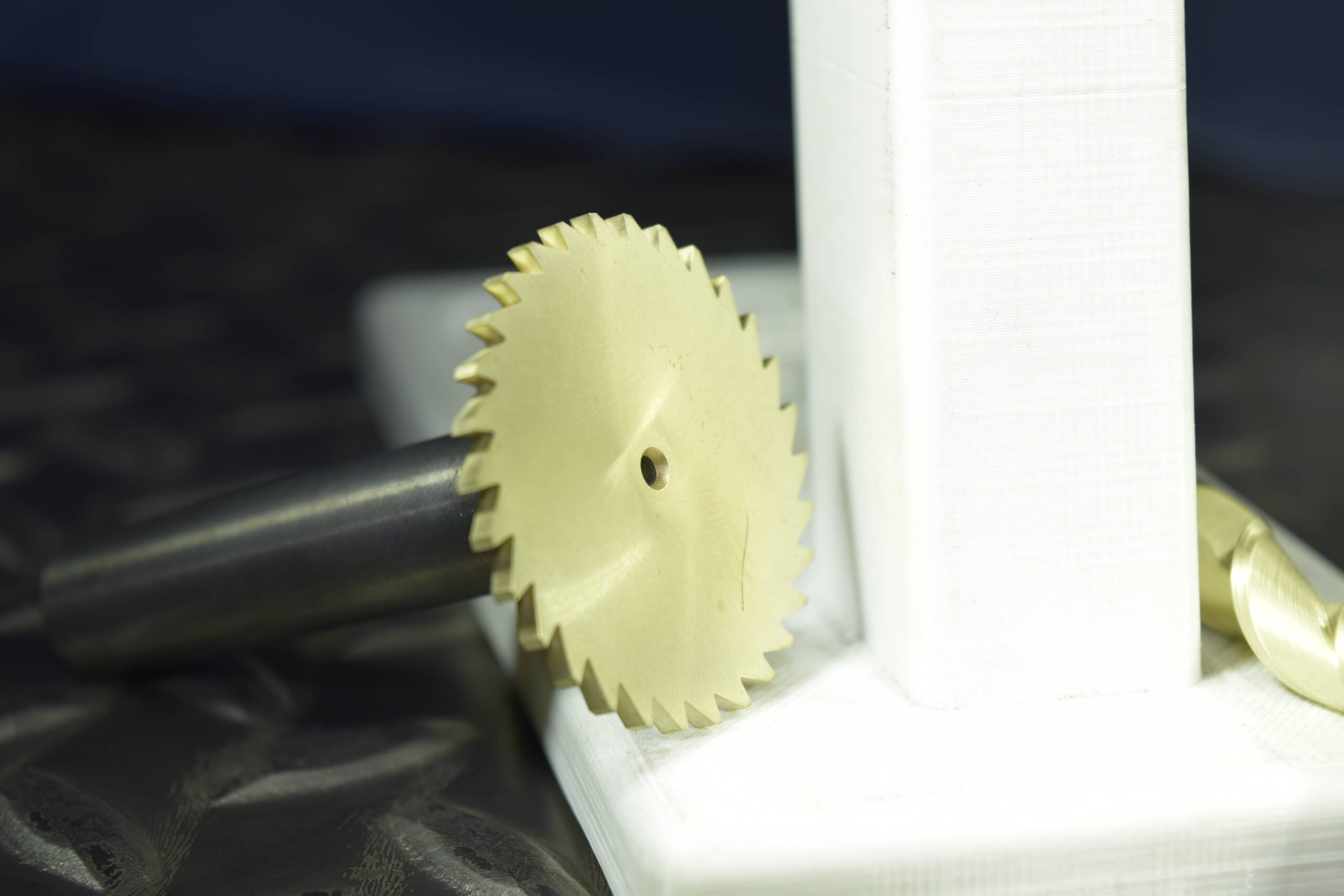

ZRN

ZRN (Mircal ALU)

Our most biocompatible ceramic hard nitride, zirconium nitride, is tougher, harder, and more corrosion-resistant than titanium nitride. It is used extensively in cutting applications. ZrN is a less expensive alternative to diamond.

Color: Light Gold

Thickness Range: 1 – 3 microns

Hardness: 2600 HV (Vickers Hardness)

Maximum Operating Temperature: 600º C (1100º F)

Lubricity: 0.35 coefficient of friction -

TeTON

TeTON

This is our best offering for machining steels in demanding conditions. Designed for Steels TeTON excels in Turning, Milling, Drilling, and Tapping. TeToN has also performed very well in the Drilling and Milling of Stainless Steel.

Color: Metal Bronze

Thickness Range: 1 – 4 microns

Hardness: 2800HV (Vickers Hardness)

Maximum Operating Temperature: 1650

Lubricity: 0.4 coefficient of friction -

Modified and Customized Coating Recipe

Our customized coating recipes can be used on a range of tools.

Want to Discuss How You Can Extend Your Tool Life?

Custom Coatings Orders On-Time,

Worldwide Shipping

We can ship Next Day Air or 2nd Day Air at your request for stated rates by the carrier of your choice. Please let us know if you wish to use your own UPS or FedEx account number before we ship back your items to avoid any uncorrectable charges by the carrier.